| Name of the Project | Amount Sanctioned | Team Members |

|---|---|---|

| Bottle Filling Project | 25,000/- | Mr. Chaitanya Kute – Student SE R & A Engineering |

| Ms. Prerna Sharma – Student SE R & A Engineering | ||

| Mr. Abhishek Malwadkar – Student SE R & A Engineering | ||

| Ms. Shrushti Thorat – Student SE R & A Engineering | ||

| Ms. Aditi Mate- Student SE R & A Engineering | ||

| Mr. Bhushan More – Student ME Design Engineering | ||

| Mr. Santosh Bhagwat – Tech. Assistant | ||

| Prof. Yogesh R Ingole – Faculty Coordinator |

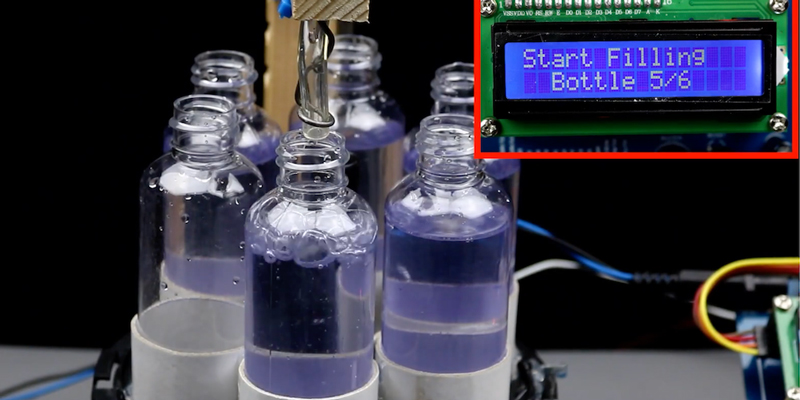

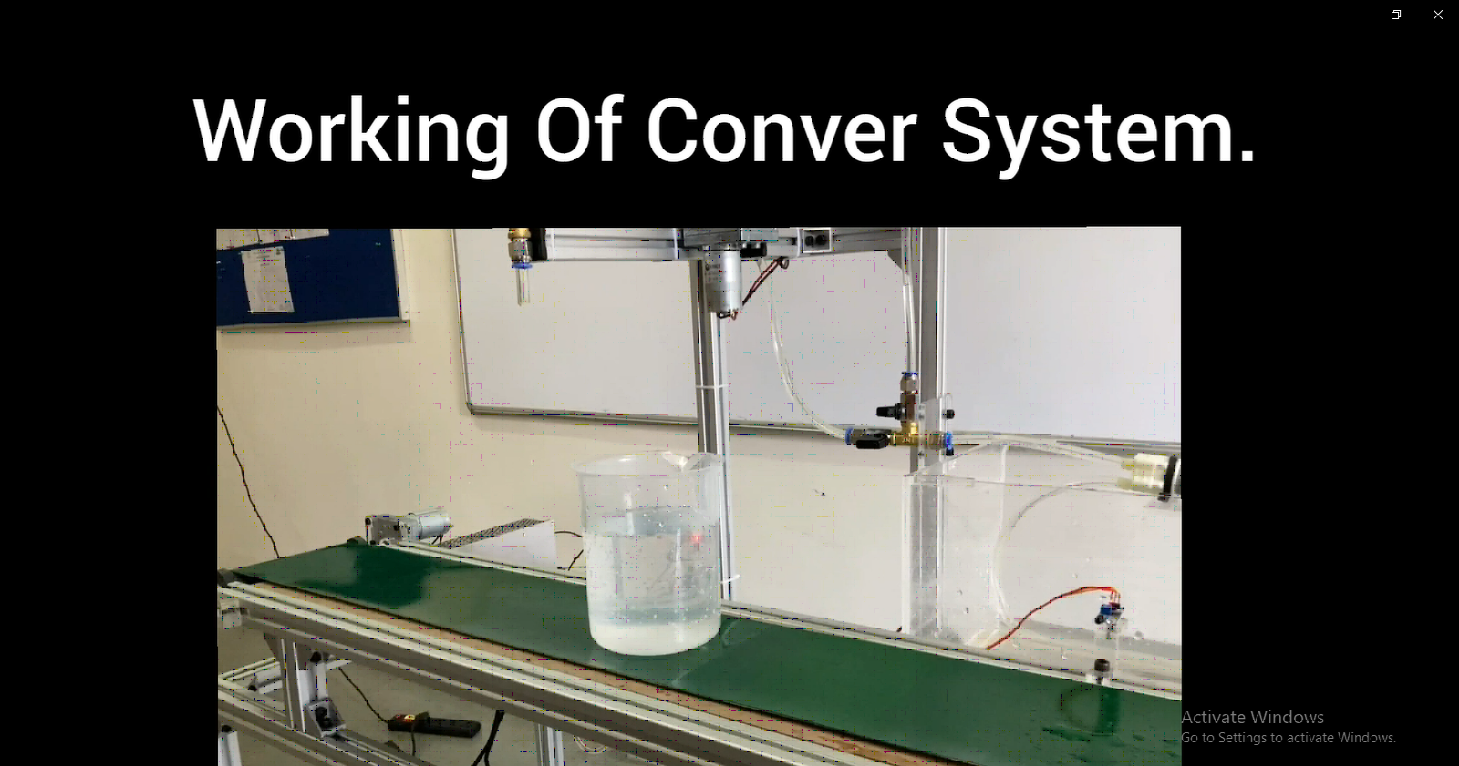

Automatic Bottle Filling Machines are most commonly used in beverages and soft drink industries. These machines use a conveyor belt which is an economical and fast way to fill bottles. Mostly PLCs are used for Automatic bottle filling machines, but you can make a very basic and versatile bottle filler using an Node MCU. You can program the Node MCU to automatically detect the bottle using IR or ultrasonic sensor and allow the bottler to fill by stopping the conveyer belt for some time. Then again move the belt and stop when the next bottle is detected.

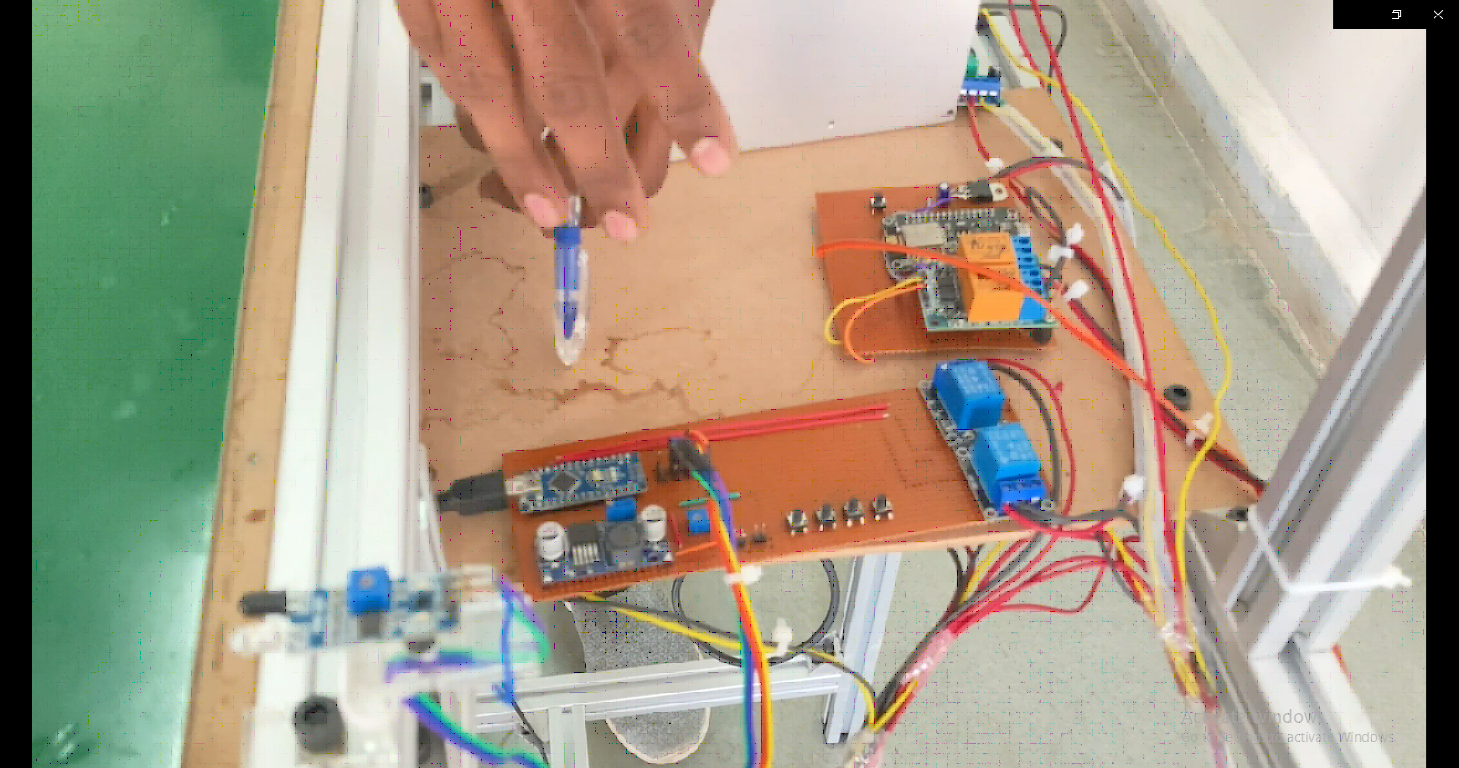

Here we are going to design a prototype for Automatic Bottle Filling Machine Plant using Node MCU, conveyor belt, IR sensor, and Gear motor. Belt conveyor is driven by a gear motor at a constant preset speed. The Gear motor will keep driving the belt until an IR sensor detects the presence of a bottle on the belt. We used the IR sensor as an external trigger. So whenever the IR sensor goes high it sends a trigger to Node MCU to stop the motor and turn on the pump. A preset required delay is already entered in the code for bottle filling. The Node MCU will keep the pump on and stepper motor off until that specified time. After that time, the pump turns off the filling, and the conveyor starts moving so that the next bottle can be filled.