Location: Hot Mix Plant, Yerwada, Pune

Date of Visit: 09th October 2025

Total Number of Students: 29

Faculty Coordinator: Prof. Rahul Matkar

Resource Person: Mr. Tushar Kare

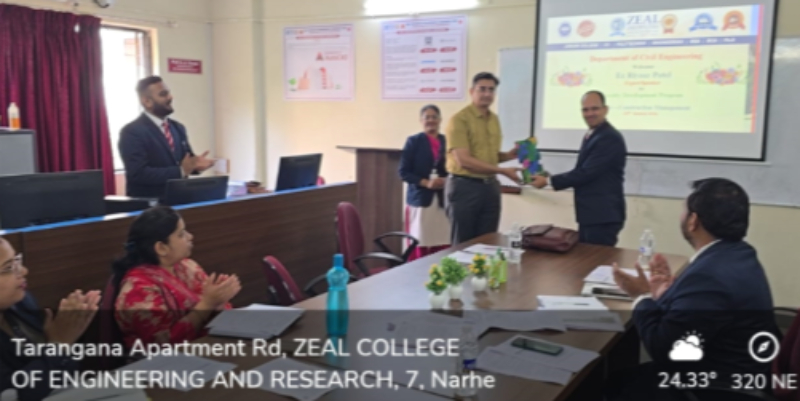

A site visit to the Hot Mix Plant located in Yerwada, Pune, was conducted on 9th October 2025, with 29 students from Civil Engg Department, Zeal College of Engineering, Pune. The visit was organized as part of the civil engineering curriculum to provide students with practical exposure to construction materials and plant operations. The resource person, Mr.TusharKare, provided a detailed explanation of the processes involved in plant operations, emphasizing material testing and aggregate sorting.

Objective:

The main objective of this site visit was to familiarize the students with the working process of a Hot Mix Plant, including the production of bituminous mixes, material testing, aggregate sorting, and standard processes involved in the manufacturing of hot mix asphalt.

Details of the Plant:

- Area of the Plant: 3 acres

- Location: Yerwada, Pune

Major Processes Observed:

Standard Processes in a Hot Mix Plant:

- Heating and Drying of Aggregates: Aggregates are heated and dried in the dryer drum to remove moisture content, ensuring proper mixing with bitumen.

- Mixing of Bitumen and Aggregates: Once heated, the aggregates are mixed with bitumen in the mixing unit. The temperature and proportions are carefully controlled to achieve the desired properties of the hot mix asphalt.

- Storage and Dispatch: The final mix is stored in silos and dispatched to the construction site in insulated trucks to maintain temperature and workability.

Processes Explained:

1. Material Testing:

- Students observed the testing methods for bituminous materials and aggregates. Various tests, such as penetration, ductility, and softening point tests, were demonstrated.

- The importance of quality control in maintaining the integrity of the final product was emphasized.

2. Sorting of Aggregates:

- The process of sorting aggregates based on size is crucial to obtaining the desired mix proportions.

- The plant uses different sieves and sorting machines to ensure that aggregates of the correct size are fed into the mixing process.

3. Standard Processes in a Hot Mix Plant:

- The students were guided through the essential processes of heating, drying, and mixing materials.

- The role of temperature control, moisture content, and proper mixing ratios in ensuring a durable final product was explained in detail.

Interaction with the Resource Person:

Mr.TusharKare answered students’ questions regarding the challenges faced in maintaining the quality of the hot mix, the environmental concerns of operating a plant, and the advancements in plant technology aimed at improving efficiency and sustainability.

Conclusion:

The site visit to the Hot Mix Plant in Yerwada was highly informative and provided students with valuable insights into the processes of material testing, aggregate sorting, and the standard processes involved in hot mix asphalt production. The practical exposure reinforced the theoretical concepts studied in class, enhancing the students’ understanding of construction materials and plant operations.