| Name of the Project | Amount Sanctioned | Team Members |

|---|---|---|

| Automated Storage & Retrieval System | 30,000/- | Mr. Chaitanya Kute – Student SE R & A Engineering |

| Mr. Bhushan More – Student ME Design Engineering | ||

| Mr. Santosh Bhagwat – Tech. Assistant | ||

| Prof. Yogesh R Ingole – Faculty Coordinator |

About Project

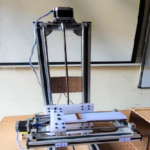

An automated storage and retrieval system (ASRS) is a device used in manufacturing plants, warehouses, and distribution centers for storing and retrieving loads from one storage location to another. An ASRS comprises various computer-controlled systems and equipment that are used to store and accurately retrieve materials. Automated Storage and retrieval System (ASRS) is an integrated, Computer-controlled, and automated material handling machine for depositing, storing and retrieving loads. The operation elements of ASRS are loading, unloading, storing, retrieving, sorting, and order-picking.

Summary

The following are conclusions that can be drawn:

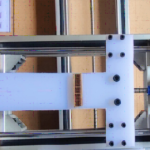

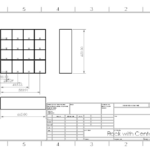

- The motion mechanism design used in the ASRS Project is the lead screw mechanism for the X axis, Y axis, and Z axis.

- The electrical module used in the ASRS system design consists of an Arduino Mega 2560 controller with shield Ramps 1.4, 12V 20A power supply, 4×4 keypad input module, and NEMA 17 & NEMA 23 stepper motor.

- Program design created using Arduino software with the basis of the C programming language and GRBL controller Software. The contents of the program are made up of coordinate mode, and auto home.

- The results of the ASRS system design of ASRS spent Rs. 30,000.00 on the material and proved to be realized by educational institutions, especially universities. The designed system ASRS is also proven to be easily operated by the operator. But from the results of the trials, the performance of speed, accuracy, and safety systems, this design still has room to be further developed.