Name of Expert: Mr. Dilip N. Bhave, R & Amp; D Manager, Hindustan Electric Motors, Mumbai.

Topic of session: Faculty development programme organized on the subject, Theory of Electrical Machine – I (SY B Tech Sem II)

Beneficiaries: All faculty of the Electrical Engineering Department

No. of participants: 11

Venue: Conference room, Department of Electrical Engineering, ZCOER, Narhe, Pune.

A. Overview:

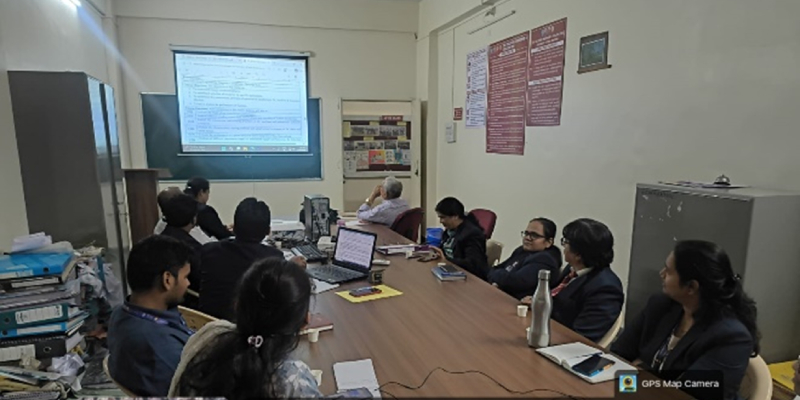

The Department of Electrical Engineering of ZES, ZCOER, Pune has organized Faculty development programme organized on the subject, Theory of Electrical Machine – I (SY B Tech Sem II) on 20/01/2026 for the faculty of the Electrical Engineering Department. This session was conducted on 20th Jan 2026 from 02:15 pm to 03:15 pm in Conference room, C-211. The session is conducted to provide detailed information and guidance to faculty about preparation for content delivery and syllabus elaboration of the subject ‘Theory of Electrical Machine – I’ to be taught to SY B Tech Sem II.

The expert speaker, Dilip N. Bhave Member of ET 15 committee on rotating electrical machines Bureau of Indian Standards (BIS) New Delhi and also Member, Technical Committee (TC2,Working group 28 and 12) International Electro technical Commission (IEC), Geneva, Switzerland.

The key points discussed in the session were as follows.

INDUSTRY EXPERT REVIEW

Course: Electrical Machines

Program: B.Tech – Electrical Engineering

The syllabus elaboration for the course Electrical Machines is found to be technically sound, industry-relevant, and well-aligned with current power and electrical manufacturing practices in India. The content adequately balances theoretical foundations, numerical problem-solving, and practical industrial exposure, making it suitable for undergraduate electrical engineering students.

The syllabus demonstrates good alignment with relevant Indian Standards (IS) and prepares students for careers in power utilities, electrical manufacturing industries, testing organizations, and maintenance sectors.

Review with Respect to Indian Standards

1. Transformers (Single Phase and Three Phase)

The coverage of single-phase and three-phase transformers is comprehensive and aligns well with the practices followed in transformer design, manufacturing, testing, and operation as per Indian Standards.

Relevant Indian Standards:

- IS 2026 (Part 1–5) – Power Transformers

- IS 1180 – Distribution Transformers

- IS 2705 – Instrument Transformers

The inclusion of:

- Equivalent circuits

- Phasor diagrams

- Voltage regulation and efficiency

- All-day efficiency

- Parallel operation

- Cooling and maintenance

- Testing procedures

is consistent with industrial testing and performance evaluation methods prescribed in IS 2026. The detailed treatment of autotransformers, including copper saving and size reduction, is particularly relevant for applications in traction systems, voltage regulation, and industrial power distribution, which are common in Indian industries.

The emphasis on Buchholz relay and conservator tank functions aligns with protection practices used in oil-immersed transformers as per Indian utility standards.

2. DC Machines

The syllabus content on DC machines reflects traditional as well as modern industrial applications.

Relevant Indian Standards:

- IS 4722 – Rotating Electrical Machines

- IS 325 – Three-phase Induction Motors (applicable principles)

The topics related to:

- Armature reaction

- Commutation improvement

- Performance characteristics

- Testing methods such as Swinburne’s and Hopkinson’s tests

are aligned with standard testing and efficiency evaluation procedures followed in Indian electrical testing laboratories and manufacturing units.

The inclusion of Permanent Magnet DC motors and Brushless DC motors enhances industry relevance, especially for applications in automation, electric vehicles, and consumer appliances, which are growing sectors in India.

3. Three Phase Induction Motors

The induction motor syllabus is highly relevant to Indian industry, where induction motors constitute a major share of electrical energy consumption.

Relevant Indian Standards:

- IS 325 – Three Phase Induction Motors

- IS 12615 – Energy Efficient Induction Motors

The elaboration covers:

- Steady-state analysis

- Torque-speed characteristics

- Losses and efficiency

- No-load and blocked rotor tests

- Impact of harmonics and unbalanced supply

These topics are directly applicable to industrial motor selection, testing, energy auditing, and maintenance practices. The inclusion of double cage and deep bar motors, along with power factor control and braking methods, aligns with real-world industrial motor control applications.

Industry Relevance and Employability

The syllabus:

- Bridges the gap between theory and industrial practice

- Encourages analytical thinking through numerical problem-solving

- Familiarizes students with testing standards, protection mechanisms, and maintenance practices

- Supports employability in power utilities, transformer manufacturing units, motor industries, and testing organizations

The inclusion of topics relevant to industrial visits, testing laboratories, and manufacturing divisions enhances experiential learning and aligns with Outcome-Based Education (OBE) principles.

Expert Recommendations

1. Testing of the machines once they are manufactured and why those tests are required.

(For ensuring quality of the product and expected service life).

2. Overall dimensions of the motors (for compact and optimum design and also during replacement)

(This also limits the lamination diameters and design). Reference of BIS standard to be taken wherever available.

3. Efficiency of the machine for lower power consumption and hence reducing the load on the Indian electrical grid. (Power ratings wise efficiency is now defined and they must be met as per BIS norms).

- For three phase induction motors, efficiencies are defined in IS:12615

- At present, there are no mandatory requirements, for efficiency of DC machines (motors and generators)

4. For DC machines (motors and generators) testing, industry follows IS:9320

You can include contents from this standard in the syllabus.

5. One visit to a manufacturing plant to see the components of the machine and complete manufacturing processes.

- Seeing is believing. If students see the components and product, they can correlate the terms used in college lectures and manufacturing plant.

Also, they can perform better in viva and industry interviews.

With the inclusion of above points, students will be ready to serve the industry better.

Conclusion

Overall, the syllabus elaboration is well-structured, industry-aligned, and compliant with relevant Indian Standards. It adequately prepares students for industrial roles, higher studies, and professional certifications in the electrical engineering domain. The content is recommended for implementation without modification, with scope for continuous enhancement through industry interaction.

Prof. Dhirendra N. Deode elaborated on the newly constructed SY B Tech syllabus of Theory of Electrical Machine – I and noted down all the suggestions received from the industry experts. The entire department faculty attended the session actively. The whole event was coordinated successfully.