Mechanical Engineering

- Mechanical Engineering

- From HOD Desk

- About Department

- Vision & Mission

- PEO – PSO – PO – CO

- Faculty Profile

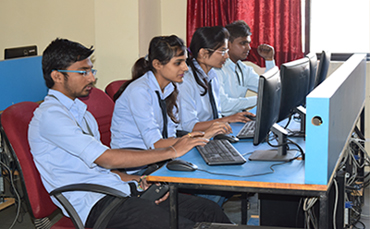

- Lab Facilities

- Research & Publications

- Skill Development

- Faculty Achievements

- Students Achievement

- Student Chapter

- Student Achievement (University)

- Students Association

- Students Placement

- Internship Details

- Final Year Projects

- PBL and Mini Project

- Center of Excellence

- Life @ Mechanical

- Downloads

- Newsletter